Scalability and Flexibility: AI-Powered Collaborative Robot for 3D Stacking and Precision Detection

Overview

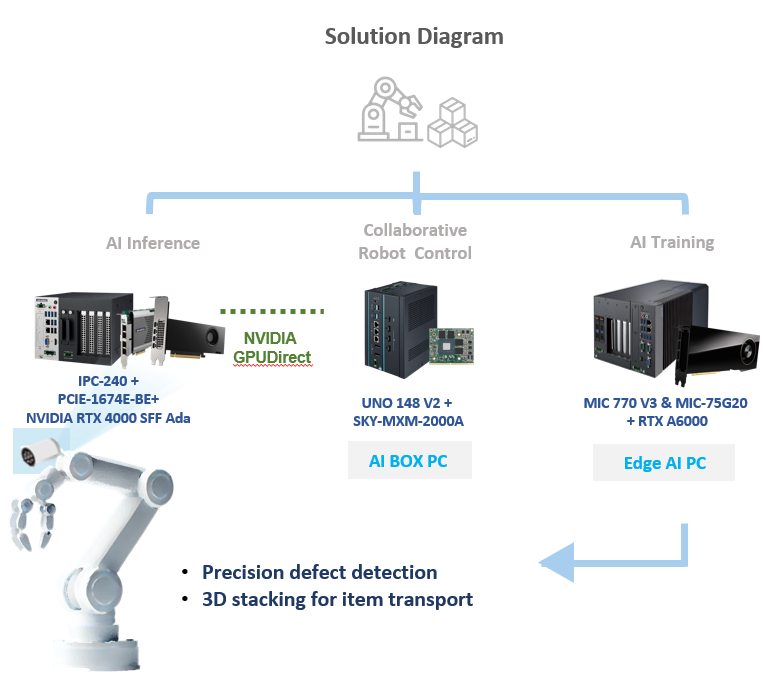

As production lines require greater accuracy in transporting and stacking goods, collaborative robots equipped with AI-powered machine vision become critical for exact positioning and alignment. Moreover, these robots can enhance quality control by accurately detecting surface defects and other flaws during operations.

Solution

Advantech’s industrial edge AI solution offers real-time vision processing to customers through a combination of compact IPC (IPC-240) with PCIe frame grabbers, AI box PCs (UNO-148 V2 with an embedded NVIDIA GPU), and Edge AI PCs (MIC-770 V3 with an NVIDIA RTX GPU). This enables precise control of AMRs and facilitates AI model training.

Benefits

•High Precision with NVIDIA GPUs and IPCs: Combining NVIDIA GPUs with advanced IPCs enhances image processing by providing exceptional precision and speed, enabling accurate and efficient execution of industrial tasks.

•Real-Time Processing with Frame Grabbers: Utilizing PCIe frame grabbers, the system processes visual data in real time, allowing AMRs to make quick decisions and adapt efficiently to changing conditions.

•Scalability and Flexibility: Our modular design ensures easy scalability and customization, making it adaptable to a wide variety of applications and environments.