Revolutionizing Egg Production: An AI-Based Optical Inspection System

Background Information

By detecting and rejecting low-quality eggs before they reach consumers, these systems help identify and remove eggs with cracks, discolorations, and other defects. This technology reduces the risk of human error and labor costs, as it automates the inspection process, reducing the need for manual labor. The system is designed to provide high-speed and high-accuracy inspections, which saves time and resources. Research has shown that AI-based optical inspection systems can improve egg grading, counting, and quality control, while increasing efficiency and reducing labor costs during the egg inspection process.

When eggs are sorted manually, the lack of precision in identifying them often leads to incorrect sorting, which in turn reduces accuracy and quality. Since the process is done manually, it requires a large number of workers to sort a relatively low number of eggs per hour, resulting in high labor costs. This low productivity rate means fewer than 1000 eggs per hour.

System Requirements

In poultry management, for a system to deliver accurate and reliable egg grading, counting and quality assessment, the following requirements must be present:

- Inspection system: High-quality, calibrated egg grading system to accurately measure egg weight, size, and shape.

- Standards: Adherence to established egg grading standards, such as USDA guidelines, to ensure consistent results.

- Training: Trained and experienced operators are necessary to accurately use the Egg Inspection System.

- Hygiene: Strict adherence to sanitation and hygiene protocols are necessary to prevent contamination of eggs and maintain their quality

- Data management: Accurate record-keeping and data management systems to track and analyze grading results

- Traceability: A traceability system tracks the history and quality of each egg, from farm to market.

System Description

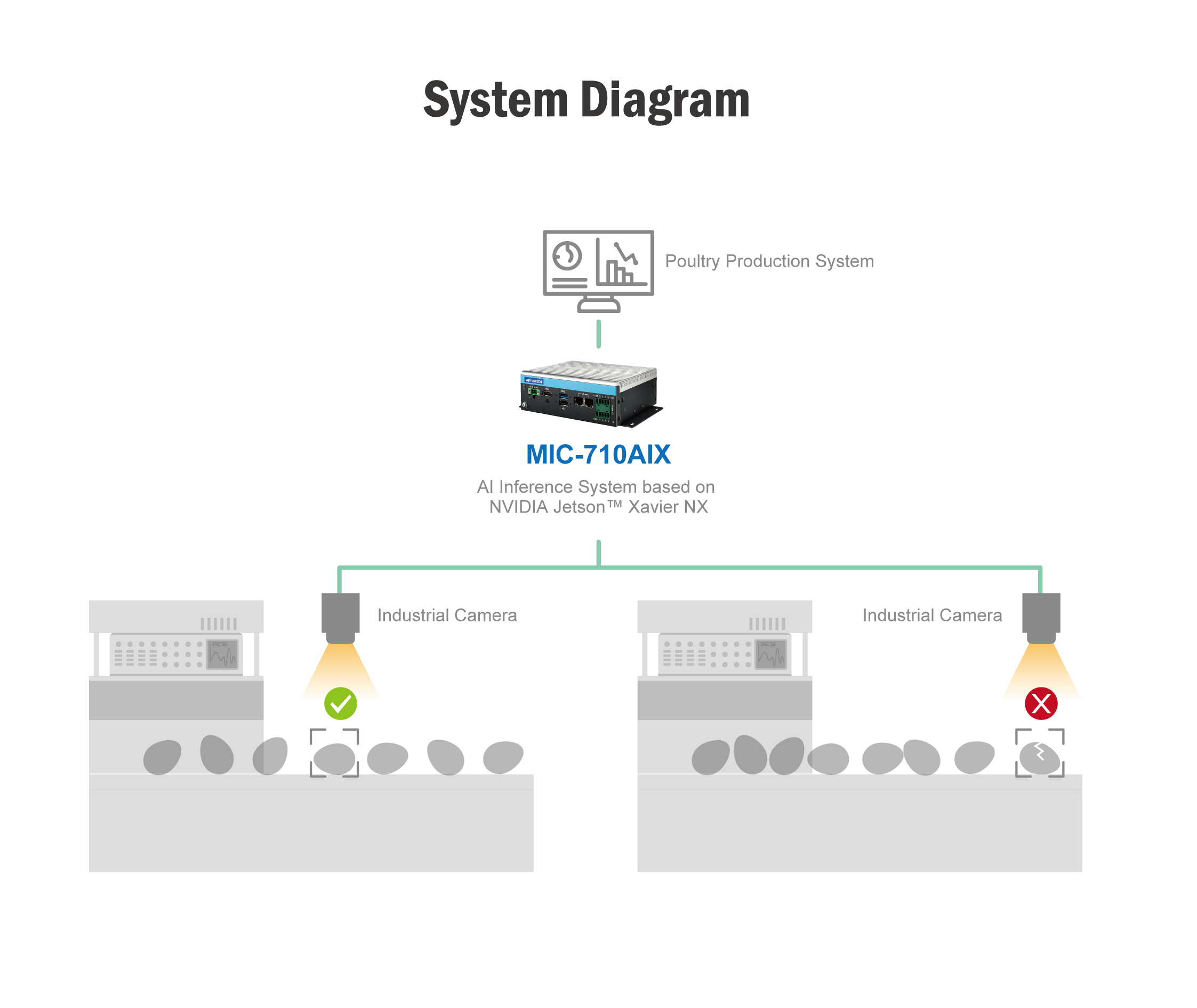

Our customer provides an AI-based automatic optical inspection system that greatly enhances the efficiency and accuracy of egg inspection. The Optical Inspection System includes a USB 3.0 camera, lamps (lighting), and the MIC-710AIX AI inference platform, which is based on the NVIDIA Jetson Xavier NX.

Flow control and AI egg inspection system:

- NVIDIA Jetson Xavier NX-based MIC-710AIX for AI inference computing to detect and identify egg defects in real time.

- High-speed, high-resolution USB 3.0 camera for enhanced image quality capture.

- Optimum field of view (FOV) lighting.

Project Implementation

Manual egg sorting is an inefficient process in the egg industry, with low productivity and high labor costs. This is why there is a need for automated sorting solutions that can increase productivity while reducing costs. The AI Optical Inspection System is one such solution that can process thousands of eggs per hour, resulting in significant cost savings for producers.

By combining industrial cameras, targeted lighting, and an AI-interface through the MIC-710AIX system, a robust technical solution is provided for the egg industry to achieve best practices in egg production, processing, and distribution

Why Advantech AI Solution

There are several benefits to using an AI-based Optical Inspection System for egg producers. Firstly, the system analyzes images of eggs and identifies cracks, discolorations, and other defects, thereby improving the quality of table eggs by detecting and rejecting low-quality eggs before they reach consumers. The inspection process is automated, which reduces the need for manual labor and minimizes the possibility of human error, resulting in reduced labor costs and increased efficiency. The system allows for high speed and highly accurate egg inspection, reducing the time and resources required to complete the inspection.

The AI-based optical inspection system, based on the MIC-710AIX, improves egg grading, counting, and quality control, while also reducing labor costs and increasing the efficiency of egg inspection processes. This ensures the brand reputation and high quality standards of the product.