Maximizing the Efficiency of Agricultural Robots

Background Information

Harvesting robots equipped with AI models and image processing can identify mature fruit and collect them using a robotic arm, resulting in efficient and accurate fruit picking. The use of these robots addresses the declining capacity of the aging rural population while also increasing efficiency and reducing production costs. Advanced farms have already implemented robots to increase productivity. The MIC-710AILX ultra-compact AI interface system is a powerful solution designed to identify and collect mature fruit with high precision and efficiency 24/7. The use of robotics and AI in agriculture is a trend that cannot be ignored as farmers seek to improve productivity and expand their fruit picking capacity.

The agricultural industry is facing a challenge as the number of people engaged in farming is decreasing while the country's elderly population is rapidly increasing. This has caused a decline in fruit picking capacity in rural areas with aging populations. However, AI and robotics technology offer a potential solution to the labor shortage problem in agriculture. Fruit picking robots have received significant attention as a method of harvesting

System Requirements

Greenhouses require modern picking robots to replace the manual labor currently used to pick fruit. With robotics and image processing, these robots can identify mature fruit and pick them individually, enhancing picking efficiency and accuracy. As a result, the system can improve productivity and reduce labor costs. This versatile solution is also suitable for other applications, making it an excellent choice for agriculture overall.

System Description

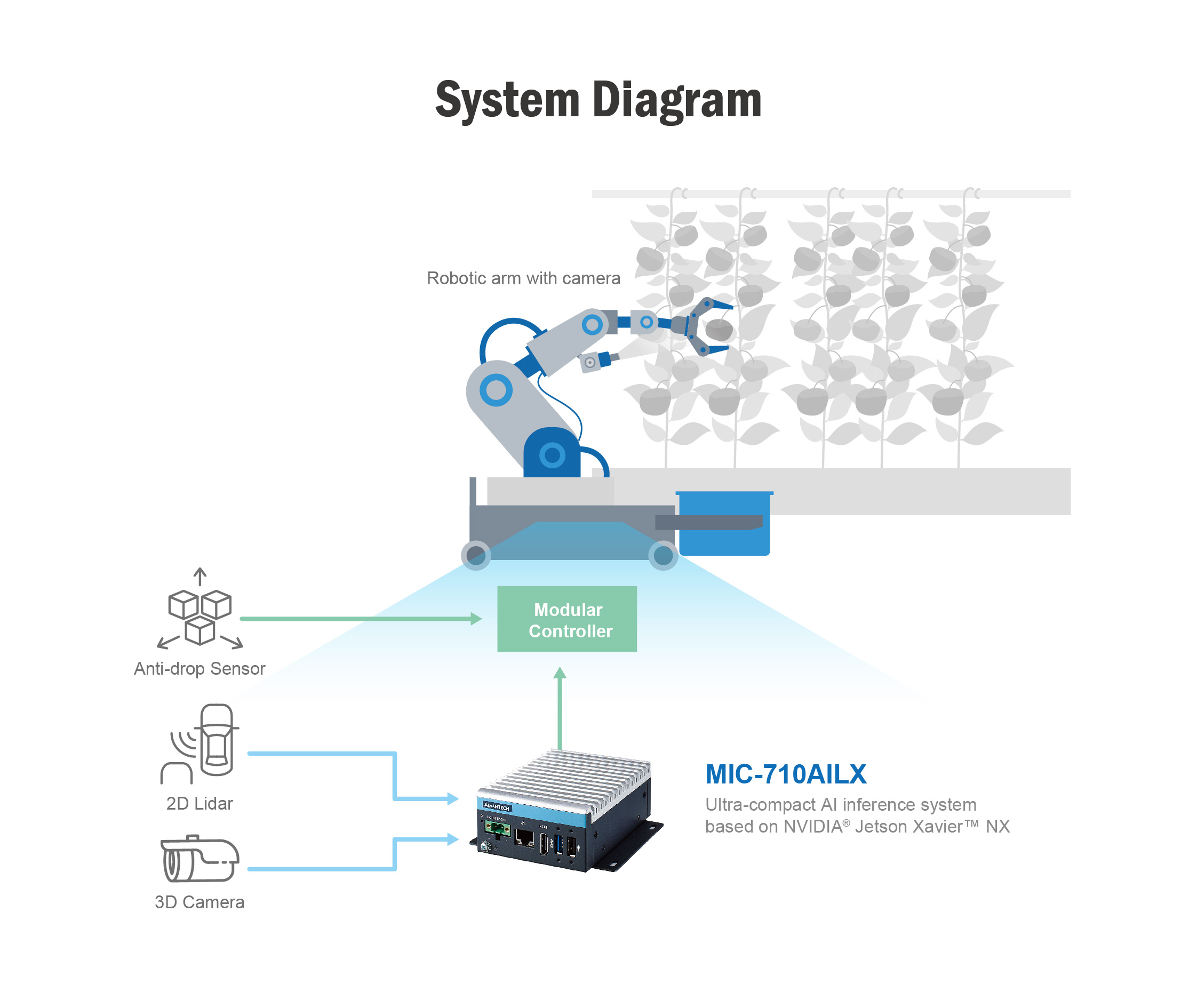

To achieve an automated fruit picking system in greenhouses a combination of hardware and software is necessary. In addition to a depth camera, a second camera is attached to the robotic arm for precise close-range positioning. With superb visual recognition, six-way vision, and accurate operation, the fruit identifier enables complete coordinate conversion and identifies fruit coordinates, and stalk positions.

At the core of the automated fruit picking system is the MIC-710AILX, an ultra-compact AI inference system equipped with powerful NVIDIA® Jetson Xavier™ NX computing. Data is gathered through the use of an anti-drop sensor, two-dimensional Lidar, and a three-dimensional camera. The anti-drop sensor alerts the system to accidents, while the two-dimensional Lidar guides the robotic arm. Fruit images are captured through the use of lighting and fixture modules and a 3D camera. AI models on the MIC-710AILX are used to identify fruit maturity, and once fruit is deemed mature, the robotic arm automatically collects it. The robotic arm collects fruit aisle by aisle, 24/7, moving on a track. With the use of this system, fruit picking can be automated, reducing the need for manual labor while improving efficiency and accuracy.

Project Implementation

The MIC-710AILX utilizes artificial intelligence models to analyze fruit and identify their stage of maturity. When a piece of fruit is identified as mature, the robotic arm automatically collects it. This system can operate 24/7, allowing for optimal fruit picking efficiency.

System Diagram

Why Advantech AI Solution

The use of AI and robotics technology can help address the decline in fruit picking capacity caused by the aging rural population. Robotics can significantly increase agricultural efficiency, and the MIC-710AILX AI-driven interface system can improve productivity by identifying mature fruit precisely for efficient picking. This is just one of the many benefits of using advanced technology in agriculture to increase the capacity of aging rural populations.