Industrial Wireless Communication Solutions Realize Digitalization and Connectivity for Tire Factory Transformations

Background

Automating factory processes starts with digitalizing and connecting production line equipment for managing overall equipment effectiveness (OEE), energy consumption, and product quality improvements. A lack of digitalization hinders data collection and analysis for extracting actionable insights. When relying on manual production line inspections, factory managers are typically notified of abnormalities and interruptions after the fact. This leads to substantial waste from defective products, extended equipment downtime, and operational bottlenecks that impact productivity.

In tire manufacturing, controlling temperature, humidity, and flow before mixing material formulas are key factors affecting tire quality. The tire production process also generally combines two main types of manufacturing. The first is continuous/batch manufacturing, where the ingredients and chemical properties differ for each batch. Thus, data visualization is necessary to control process-based production. The other type is discrete manufacturing, which involves a single component and minimal variation, but requires digitization of the entire manufacturing process.

However, for tire manufacturers with traditional factories full of legacy infrastructure, upgrading off-line equipment is difficult because of non-stop production demands. Accordingly, machine operators still rely on paper records for documenting errors and on-site engineers still monitor equipment operations manually. This approach is time consuming and prone to errors, in addition to generating high personnel resource and maintenance costs.

System Requirements

To improve the efficiency of on-site management, equipment and environment data must be digitalized for real-time visualization and process integration. For managing operational technology (OT), comprehensive data of energy consumption and transformer operations must be collected to effectively improve production efficiency.

The automobile tire manufacturer needed solutions for remote sensing of key processes, parameter thresholds, equipment status, as well as environmental temperature and humidity data. However, the manufacturer’s production line comprised mainly offline equipment installed at considerable distances from each other, making it impractical to install network cables for connectivity. Instead, the production processes relied on manual paper-based inspections and record-keeping, which is difficult to track and manage.

To address these issues, the manufacturer wanted a solution that could be deployed without disrupting operations or requiring additional wiring. Ideally, they wanted wireless I/O modules that could be integrated with existing equipment for data acquisition and transmissions. To upgrade the factory within budget, the solution also needed to be cost effective and easy to install for remote smart factory data monitoring and analysis.

Project Implementation

- WISE-4220-S231: 2.4G Wi-Fi IoT Wireless Module with Temperature & Humidity Sensor

- WISE-4220 + WISE-S214: 2.4G Wi-Fi IoT Wireless Modular I/O + 4AI/4DI Wireless Modular I/O

- WISE-4051: 8DI 2.4G Wi-Fi IoT Wireless I/O with 1RS-485

- WISE-4060: 4DI/4Relay 2.4G Wi-Fi IoT Wireless I/O

System Description

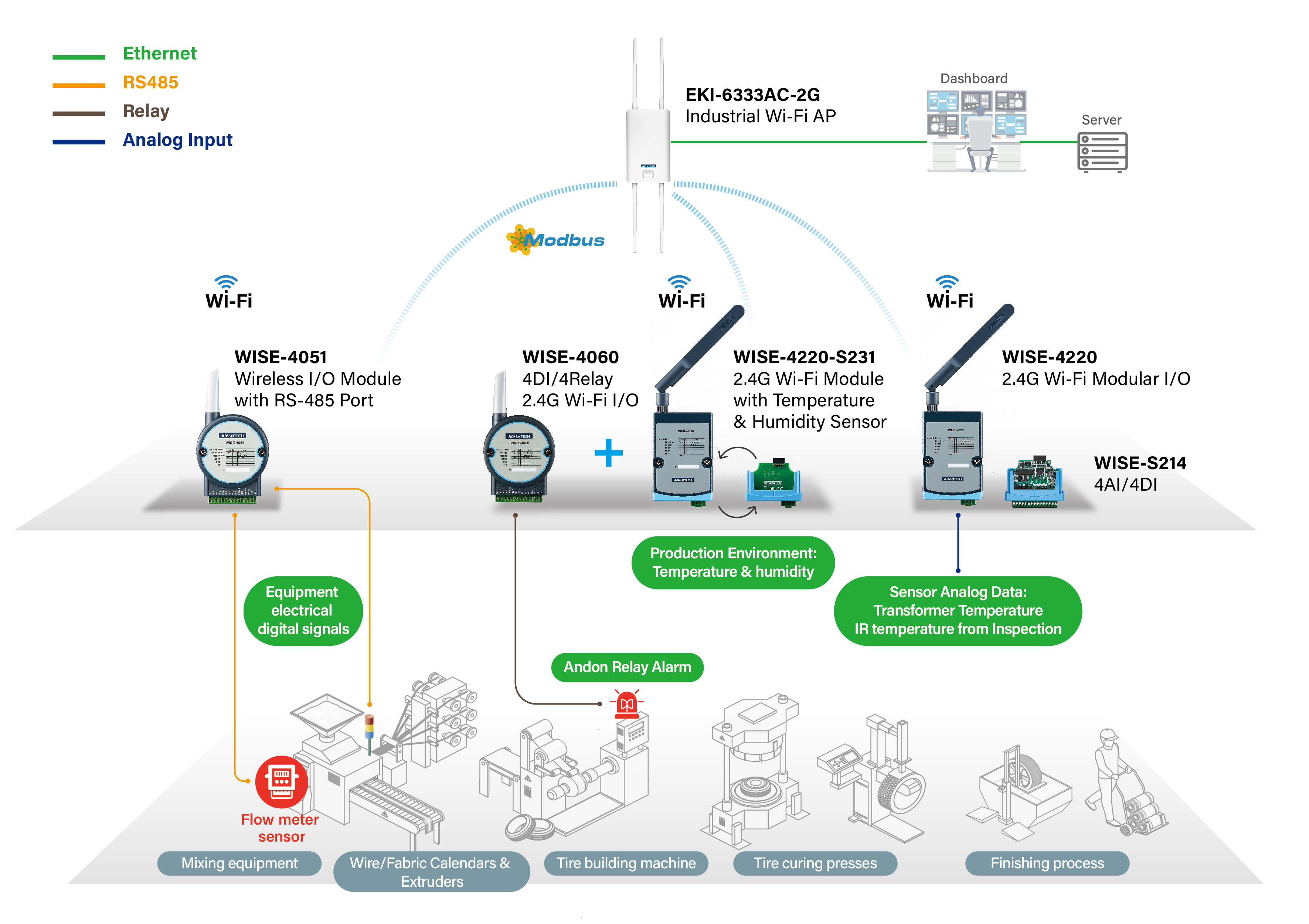

For this project, Advantech’s WISE-4220-S231, WISE-4220 +WISE-S214, and WISE-4051 wireless I/O modules were deployed as the data acquisition layer and a WISE-4060-B module was used as an alarm provider.

WISE-4220 is a wireless module that can be matched with different I/O boards, while WISE-4060 supports relay output. The upper-level monitoring system is used to set various alarm value thresholds. When these thresholds are reached, the system sends alarm signals to the alarm device through WISE-4060 to facilitate immediate on-site management. Data is transferred to the MES/SCADA system via Modbus and then transmitted to the private server/cloud using the MQTT protocol.

WISE-4220-S231 is a wireless data acquisition module that combines WISE-4220 with a temperature and humidity sensing chip module to convert local sensing data into intelligence for remote applications using the Modbus TCP protocol. The tire manufacturer chose WISE-S214 because most sensors do not support RS-485 + Modbus and only transmit analog voltage signals. However, the WISE-4051 module can obtain Modbus RTU-supported, RS-485 interface, flow sensor data from mixing equipment directly. This allows the signals collected through the I/O on the lower board to be transmitted using the Modbus protocol to the upper server for integration with the management platform.

System Diagram

Benefits

The automobile tire manufacturer succeeded in implementing a remote monitoring system that enabled them to reduce energy consumption, optimize system availability, and improve the quality of tire products. The first step involved collecting production line data for remote visualization and machine operations monitoring. In the second stage, environmental and energy consumption data were leveraged to optimize workplace safety and energy efficiency. For the third and final stage, an alarm solution was established for managing process abnormalities in real time.

Advantech’s WISE series of wireless communication modules offer multiple I/O and plug-and-play functionality for flexible deployment in both indoor and outdoor environments. These modules can be employed for networking legacy equipment and conducting comprehensive remote monitoring of all infrastructure, including monitoring of production/storage environments, facility energy consumption and efficiency, and manufacturing process parameters.

Because of the successful realization of comprehensive equipment networking and remote operations monitoring, the tire manufacturer decided to extend Advantech’s solution to its other R&D centers and production facilities, including four factories in China. By offering extensive support for diverse PLCs, Advantech’s wireless communication modules eliminate complex construction and cabling efforts, allowing manufacturers to quickly upgrade their factory capabilities while saving installation time and cost.

Why Advantech

Advantech provides an extensive portfolio of mature, industrial-grade products that can be easily configured to deliver breakthrough solutions. For manufacturing automation applications, Advantech offers comprehensive networking infrastructure and wireless communication equipment, including edge sensors, data gateways, and server storage devices.

Additionally, Advantech can assist customers with integrating unique systems and extended functions according to specific usage requirements. From hardware components to integrated systems, Advantech products offer easy deployment, operational reliability, high compatibility, and flexible expansion for a range of future applications.