Advantech Industrial Monitor Boosting Efficiency

As the demand for electronic devices continues to grow, traditional manual testing methods are no longer sufficient to meet production requirements. As a result, the adoption of automated testing systems has become a necessary solution. This case focuses on an electronic devices testing line that includes over twenty testing stations, designed to improve testing efficiency while reducing labor costs.

System Requirements and Benefits

For the optimal operation of the automated production line testing, several key system requirements were essential:

- Enhanced Touch and Visibility

The production line required a 16:9 touchscreen monitor with a reliable glass surface using P-CAP touch technology. These features ensure excellent visibility, improve operational comfort, and allow for clearer monitoring of the testing process, ultimately reducing error rates.

- Easy Installation

The slim panel-mounted design facilitates straightforward installation, maximizing space efficiency on the testing line.

- Industrial-Grade Design

The system design needed a 24V DC power supply and ruggedized chassis were essential to meet the demands of the harsh industrial environments they operated in.

- Cost-Effective

By reducing over reliance on manual labor, the system significantly lowered operational costs compared to previous testing methods.

System Description

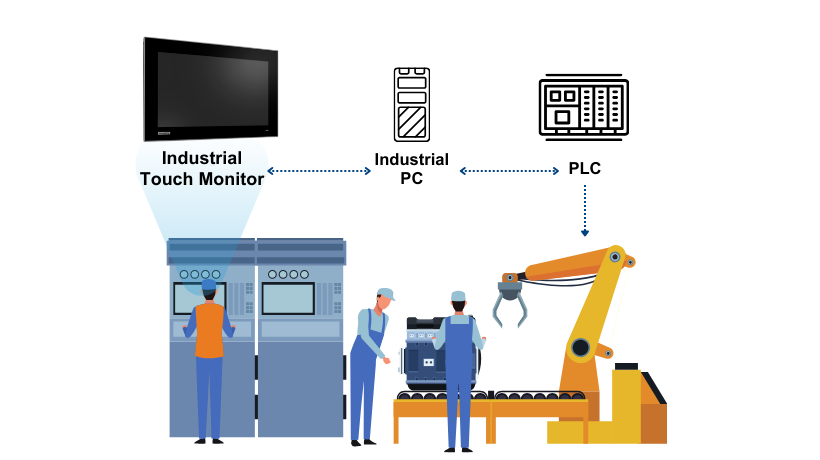

he advanced automated testing system integrates three key components that work in perfect harmony. At its core is Advantech's industrial-grade monitor from the FPM-700 series, specifically the 15.6" FPM-715W, which serves as the primary user interface, providing real-time visual feedback. The monitor connects directly to an Industrial PC (IPC), processing data, and managing testing protocols.

The IPC communicates with a Programmable Logic Controller (PLC), which coordinates the physical aspects of the testing process. The PLC controls various testing stations and synchronizes robotic systems, ensuring precise timing and execution of each test. The system enables efficient data flow from the user interface to the testing sensors, facilitating rapid, accurate, and highly automated electronics device testing.

The integrated system greatly improves testing accuracy, reduces processing time, and provides robust data analysis capabilities, leading to significant improvements in product quality and operational efficiency.

Why Choose Advantech Industrial Touch Monitor?

Advantech's extensive experience in industrial automation has positioned the FPM-700 series as a market leader, recognized for its high performance and reliability. Our industrial monitors are tailored to meet the specific demands of automated testing environments.

- Monitor sizes range from 15.6" to 24", featuring P-CAP touch technology for excellent visibility and user comfort, perfectly aligning with system requirements.

- Built with a rugged die-cast aluminum chassis, IP66 rating, and a wide operating temperature range from -20°C to 60°C, the FPM-700 series is engineered to endure challenging industrial conditions.

- The slim, panel-mounting design and support for both USB and RS-232 touch enable easy integration into testing lines, maximizing space utilization.

- Advantech’s industrial-grade components come with standard industrial certifications including CE, FCC, UL, BSMI, CCC, and EU energy-related products (ErP), ensuring stable performance and extended product lifecycles, while reducing long-term operational costs.

- With quick delivery and easy setup, Advantech allows customers to activate their systems promptly, minimizing downtime.