Air Compressor Manufacturer Creates New Service Model with IoT Edge Technology

Introduction

Compressed air is used as a major source of energy transfer that drives many of today’s manufacturing processes and is widely used in many industries and applications, such as heavy lifting and conveyance, tire inflation, dust removal, painting and coating, vacuum packaging, cutting and sawing, and much more. An unexpected failure of air compressor equipment in any workplace will lead to costly downtimes and increased production line costs. Advantech worked with air compressor manufacturer SWAN to deliver a solution for their products.

Several top players in the industry have competed to add intelligence to their products in their initial designs to enable their equipment to be connected, communicate, and transmit data, so that their air compressors will autonomously report operational status and performance parameters to the compressor operators, and if required, send out warnings to maintenance and service engineers so as to fix breakdowns quickly but also be more preventative next time.

SWAN is a well-established air compressor manufacturer based in Taiwan who sought help from Advantech to work out an IoT solution to establish remote data monitoring for their rotary screw compressors and reciprocating compressors—which are two of the most commonly used types of air compressors in today’s industry.

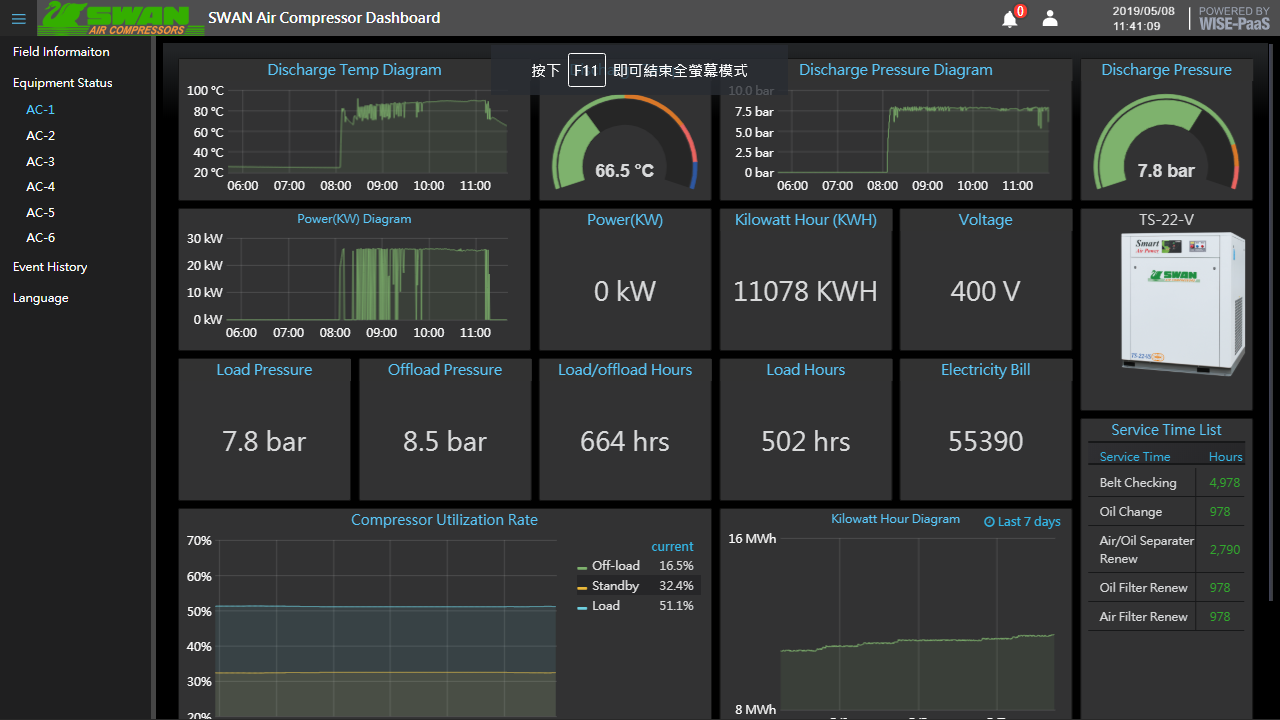

The equipment data is collected and sent to an intelligent edge server and a cloud platform for analysis on the performance patterns of the serviced compressors, so that the compressor users and their maintenance service providers can keep an eye on the health and the operational status of their equipment, including the temperature, pressure, air flow, and the conditions of major components such as motors, belts, bearings, oil separator, and air filters. The monitoring system will send warnings of problems and trigger a visit by maintenance and service engineers onsite if there are any breakdowns. The compressor manufacturer’s cloud service will also issue alerts to remind specific users of component renewals before deadlines arrive.

Application Requirements

The project solution needed to build in methods to acquire data from the air compressors deployed in the workplace. It also needed to analyze and visualize the data in real time for remote monitoring. Historical databases also needed to be established for implementing big data analytics. The customer also hoped that warnings, alerts, and notifications could be sent via e-mails and messages, including a countdown mechanism to remind compressor users in advance of the due dates of the component warranty period and its service life left available.

Consequently, an edge computer was to be deployed at the user’s workplace to implement efficient data collection and analysis. The computer sends acquired data up to the cloud platform to allow the equipment manufacturer and their local service providers to keep track of the condition of their air compressors. The cloud service was optional so customers could also choose not to upload data via a cloud service if they preferred.

The rotary screw compressor is a more advanced type of air compressor and has an inherent digital controller, so they can simply use a serial line or employ wireless to connect the edge computer to the compressor controller to acquire data. As for the more traditional reciprocating air compressor, which has no controller inside the equipment, we had to deploy an add-on data acquisition module to connect with external meters, switches, or sensors for acquiring operations data, which then gets sent to the edge intelligence computer for analysis via Modbus, Internet, or wireless connection.

Solution

The Advantech EIS-D210 edge intelligence server, running on an Intel Celeron N3350 processor, is a small and compact computer delivering abundant processing power. The compact size allows it to fit into the rotary screw compressor’s equipment without the need to change the design of compressor’s original form factor. Equipped with a WiFi module, the EIS-D210 could easily connect with the compressor’s control unit to acquire operational data.

In addition to a WiFi connection module, the EIS-D210 also provides serial COM ports, so that it can easily connect with the edge server and the compressor controller via a serial line. The serial COM port can also be used to connect with the power meter to acquire values such as voltage, current, power, KW, and KWH for energy analysis and efficiency savings.

Most important, each EIS-D210 is pre-installed with Advantech’s IoT device operation WISE-PaaS/DeviceOn management platform, which empowers the edge server with IoT gateway capability able to convert all kinds of industrial field communication languages into standard IoTprotocols. This IoT edge computing feature allows the system to be easily and quickly deployed in a variety of industrial scenarios and application environments.

WISE-PaaS/DeviceOn also provides a multitude of APIs for system designers to develop application features with ease, including customizable dashboard for visualizing data and analyzing results, sending customized messages and much more. Cross-platform capabilities link with applications such as e-mails and Line messaging to allow compressor users to keep track of their equipment status with their mobile devices at anytime from anywhere.

Benefits

- Powerful connectivity and data acquisition capabilities help the customer quickly deploy IoT and integrate field data with backend management.

- Pre-installed IoT software platform provides a multitude of APIs to develop customizable dashboards and messages and integrate cross-platform data and applications.

- Compact form factor and excellent processing power allow the edge server to be built into the rotary screw compressor equipment and connect with the compressor controller unit directly.

- Successfully introduces Industry 4.0 elements into SWAN air compressors and allows customers to inaugurate preventive maintenance, which adds value to their compressor products, minimizes unexpected equipment breakdowns, reduces the needs for real life visits by maintenance and service engineers, and brings industrial and business transformation.